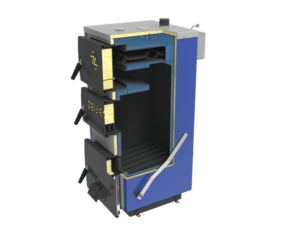

*Zdjęcie poglądowe

KWK

Suitable for every building

The all-purpose KWK type boiler is a heating unit with the upper combustion of solid fuels. It is especially popular in private homes, but it is also installed in commercial spaces and individual shops. It is designed to burn such fuels as wood, hard coal, and coke.

Easy to use

Thanks to the unfailing upper-combustion design, every kind of fuel will be burnt almost completely. Fuel catches fire quickly and easily – it is enough to strike one match on the grate and fire will spread rapidly over the fuel. To ensure maximum efficiency of operation, we recommend fitting an automatic draught regulator. Also, the KWK boiler is fitted with a movable grate which can be easily emptied of ash.

Heat efficiency reaching 82%

The KWK from ZGM ZĘBIEC SA features a large combustion chamber enabling the burning of both hard coal and sizeable pieces of wood. The larger chamber can receive a bigger charge at one loading. The fuel charge burns evenly, ensuring a constant temperature in the heating medium. Simultaneously, with a view to enhancing heat transfer, the KWK boiler contains one extra path for the flue gas (the so-called water pocket) as well as a fixed water grate.

Only proven and durable materials used

KWK boilers are made only using proven and durable materials ensuring long service life. The use of certified boiler plates of 6 mm in thickness and an insulation mantle made of steel cassettes that are lined with mineral wool has a radical impact on the reliability of the design.

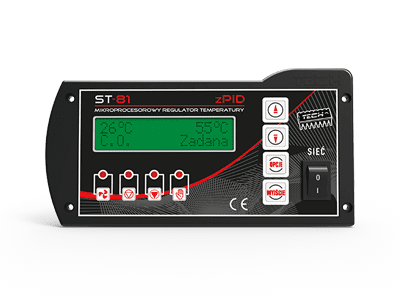

Option of automatic operation

The boiler is designed to accept a PID algorithm control module, which guarantees high accuracy of parameter control and reduces the user’s involvement to a minimum. However, the boiler is also the perfect choice for periods without electricity, using the natural air draught. Temperature can be adjusted using an air throttle located in the ash pan door, or an automatic regulator (the so-called draught regulator).

Large combustion chamber.

Designed for the self-assembly of the control kit, which is available as an option at an extra charge..

Combustion is controlled by means of an automatic draught regulator* or manually (*as an option at extra charge).

High combustion efficiency, up to 82%.

Certified boiler plates P265GH.

Szybkie i skuteczne odpopielanie dzięki ruchomemu rusztowi żeliwnemu.

60-month warranty for the leak-tightness of the water jacket.

24-month warranty for service life and efficient operation.

|

|

|

| Hard coal | Hard coal + coke | Wood |

Manual

By means of a screw adjusting the position of the flap in the lowest door

Automatic

By means of a draught regulator

| BOILER | Height | Width | Depth | A | B | C | Flue | Burning chamber | Charging hole | E | |||

| D | height | width | depth | width | height | ||||||||

| KWK 12 | 1014 | 320 | 650 | 253 | 886 | 1058 | Ø 130 | 230 | 214 | 376 | 146 | 199 | 381 |

| KWK 16 | 1025 | 382 | 686 | 253 | 878 | 1070 | Ø 170 | 290 | 276 | 376 | 212 | 167 | 447 |

| KWK 25 | 1140 | 506 | 752 | 280 | 1001 | 1185 | 170X170 | 290 | 400 | 397 | 317 | 197 | 570 |

| Lp | Detailed data | Jedn. miary | KWK 12 | KWK 16 | KWK 25 | |

| 1 | Rated thermal output | kW | 12 | 16 | 25 | |

| 2 | Standard fuel | hard coal | ||||

| 3 | Charge capacity of the burning chamber | dm3 | 19 | 30 | 47 | |

| 4 | Boiler water capacity | dm3 | 30 | 35 | 58 | |

| 5 | Max. water temperature | °C | 95 | 95 | 95 | |

| 6 | Min. required draught | Pa | 22 | 24 | 25 | |

| 7 | Min. chimney height | m | 5 | 5 | 5 | |

| 8 | Max. operating pressure | bar | 1,5 | 1,5 | 1,5 | |

| 9 | Min. chimney cross-section area | cm ´ cm

Æ cm |

14×14

Æ 14 |

20 x 14

Æ 18 |

20 x 14

Æ 20 |

|

| 10 | Flue diameter | mm | Æ130 | Æ170 | 170×170 | |

| 11 | Heat efficiency with standard fuel at rated power | % | do 82 | do 82 | do 82 | |

| 12 | Net weight | kg | 157 | 185 | 285 | |

| 13 | Overall dimensions | height

width depth (incl. flue) |

mm

mm mm |

1014

320 650 |

1025

382 686 |

1140

506 752 |

| ZĘBIEC boilers | Thermal output | Heated floor area [m2], based on the heat transfer coefficient of the walls (insulation) | |||

| U 1 [W/m2K] | U ~ 0,7 [W/m2K] | U ~ 0,5 [W/m2K] | U ~ 0,3 [W/m2K] | ||

| no insulation | ~5cm styrofoam | ~8cm styrofoam | ~10cm styrofoam | ||

| KWK 12 | 12 | 105 | 120 | 140 | 185 |

| KWK 16 | 16 | 135 | 160 | 190 | 245 |

| KWK 25 | 25 | 215 | 250 | 295 | 385 |

Draught regulator

A draught regulator in solid-fuel boilers is a thermostatically operated device for controlling the water temperature in the boiler.

The thermostatic head of the regulator monitors the water temperature in the boiler and via levers and a chain actuates a flap to increase or reduce the airflow into the hearth.