*Zdjęcie poglądowe

KMW

Popular boiler for fine coal

KMW from ZGM ZĘBIEC SA is an upper combustion heating unit which uses fine coal as fuel. If necessary, it will use hard coal or wood logs. The boiler is perfect for residential and utility buildings, commercial spaces and garages.

Easy stoking

The large stoking door ensures easy replenishment of fuel, and the sizeable combustion chamber will hold fuel for at least 20 hours of heating. Such a duration of sustained burning is achieved by the use of a large enough combustion chamber, an efficient heat exchanger, and a controller which ensures steady burning.

Safe operation

The operation of the boiler is supervised by safety devices and sensors which react in due time and signal failures or threats. As standard, the KMW boiler is fitted with water and exhaust temperature sensors. All of these features contribute to thermal efficiency and safe operation of the unit.

Efficient combustion

Fine coal KMW boilers are efficient and popular heating units which work in thousands of Polish homes. This model features modern solutions which increase its heat efficiency. In the basic configuration, the unit is fitted with a fan blower and a controller, which maintains the temperature of the water in the boiler jacket. The multi-point air supply system ensures uniform and sustained burning, so the unit works longer and more efficiently, and the fuel does not need to be replenished frequently. The exchanger is made of certified boiler plates and insulated with mineral wool, which minimises heat loss even better.

Easy to use

Fine coal heating boilers from ZGM ZĘBIEC SA are valued for their high combustion efficiency, thermal efficiency and convenience of use. Easy cleaning and maintenance are its advantages, too, making KMW boilers perfect heating units for all of those who appreciate convenience of use.

Large combustion chamber.

High combustion efficiency, up to 82%.

Certified boiler plates P265GH.

Sensors and systems: leaving water temperature sensor, flue gas temperature sensor, boiler water mechanical temperature limiter (STB), boiler water temperature sensor.

Electronic controller managing the operation of:

– central heating pump,

– domestic hot water pump,

– fan blower.

24-month warranty for leak tightness of the water jacket.

24-month warranty for service life and efficient operation.

12-month warranty for exhaust temperature sensor.

|

|

|

| Fine coal | Hard coal | Wood |

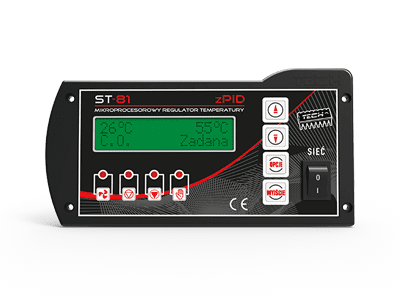

ST-81zPID controller

The ST-81zPID controller is in charge of a continuous regulation of the air inflow, and the control of the central heating and utility water pumps.

It is fitted with boiler temperature and exhaust gas sensors. It is made from high quality materials, which are resistant to high and low temperatures.

| BOILER | Height | Width | Depth | A | B | C | Flue | Burning chamber | Charging hole | F | G | ||||

| D | E | Hi | Wi | De | Wi | Hi | |||||||||

| KMW 16 | 1095 | 398 | 709 | 246 | 997 | 1155 | 170 | 170 | 377 | 224 | 397 | 212 | 167 | 178 | 412 |

| KMW 23 | 1266 | 522 | 900 | 261 | 1135 | 1324 | 170 | 170 | 376 | 348 | 397 | 312 | 243 | 198 | 563 |

| KMW 30 | 1438 | 530 | 850 | 93 | 1219 | 1428 | 170 | 170 | 409 | 346 | 500 | 312 | 243 | 207 | 583 |

| L.p. | Detailed data | UOM | Boiler size | |||

| KMW 16 | KMW 23 | KMW 30 | ||||

| 1 | Rated thermal output | kW | 16 | 23 | 30 | |

| 2 | Operating range | kW | 5÷16 | 8÷23 | 10÷30 | |

| 3 | Standard fuel | fine coal | ||||

| 4 | Charge capacity of the burning chamber | dm3 | 38 | 57 | 82 | |

| 5 | Boiler water capacity | dm3 | ~57 | ~78 | ~115 | |

| 6 | Required draught | Pa | 24÷34 | 25÷35 | 25÷35 | |

| 7 | Min. chimney height | m | 5 | 7,5 | ||

| 8 | Min. chimney cross-section area | cm x cm

Æ cm |

20×14

Æ 20 |

|||

| 9 | Flue diameter | mm | 170×170 | |||

| 10 | Max. operating pressure | bar | 1,5 | |||

| 11 | Max. water temperature | °C | 90 | |||

| 12 | Heat efficiency at rated power | % | do 82 | do 82 | do 82 | |

| 13* | Single-charge sustained combustion at rated/minimal power | h | ~9/~21 | ~10/~30 | ~11/~32 | |

| 14 | Connection pipes, leaving/return water | mm | Æ48,3×4 (1 1/2”) gwintowane | Æ60,3×4 (2”) gwintowane | ||

| 15 | Net weight of empty boiler | kg | 220 | 282 | 420 | |

| 16 | Overall dimensions | height | mm | 1095 | 1266 | 1438 |

| width | mm | 398 | 522 | 530 | ||

| depth (incl. flue) | mm | 709 | 900 | 850 | ||

| 17 | Power supply | ~230V/50Hz | ||||

| 18 | Power consumption | regulator | W | 4 | ||

| fan blower | W | 25 | ||||

| 19 | IP rating | regulator | IP 20 | |||

| fan | IP 44 | |||||

| ZĘBIEC boilers | Thermal output | Heated floor area [m2], based on the heat transfer coefficient of the walls (insulation) | |||

| U 1 [W/m2K] | U ~ 0,7 [W/m2K] | U ~ 0,5 [W/m2K] | U ~ 0,3 [W/m2K] | ||

| no insulation | ~5cm styrofoam | ~8cm styrofoam | ~10cm styrofoam | ||

| KMW 16 | 5÷16 | 135 | 150 | 180 | 235 |

| KMW 23 | 8÷23 | 200 | 230 | 270 | 350 |

| KMW 30 | 10÷30 | 260 | 300 | 350 | 460 |

…