*Zdjęcie poglądowe

SWK

Fail-safe design for 40 years

The SWK boiler with the upper combustion of solid fuels ensures the efficient heating of any type of building: from a garage, a house and utility buildings to commercial spaces. Due to a great deal of interest in the SWK, the boiler is modernised on a regular basis to accommodate modern solutions as well as possible to achieve better combustion parameters.

Practical solution for more convenient operation

The large combustion chamber and an efficient system of ash removal via a movable grate are but a few solutions enhancing the convenience of use. On top of that is a rugged and heat-resistant structure, making SWK one of the most commonly bought models from ZGM ZĘBIEC SA.

Economical combustion thanks to automatic regulator

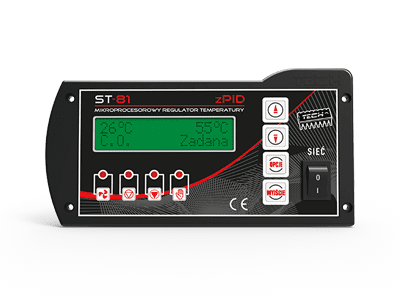

The sizeable burning chamber is a great advantage as it prolongs the uninterrupted operation of the boiler. The SWK is designed to use a system based on the PID algorithm to control the process and economy of fuel combustion. In the event of power failure, the boiler works well and ensures satisfactory performance relying on natural draught. The user can set the temperature by means of an adjustment screw located in the bottom door which regulates the position of a flap (mechanical) or this can be adjusted by a draught regulator.

High thermal efficiency, reaching 82%

The SWK is made only from proven and durable materials. Heat dissipation is significantly reduced by means of an insulation mantle made with layers of steel lined with mineral wool. The high efficiency (up to 82%) is made possible by, among other things, a recycled air throttle, which enhances the burning parameters and enhances gas burning in the combustion chamber. Additionally, the ash pan used here is an integral part of the boiler body. This eliminates turbulences of burning resulting from unwanted air flow.

Large combustion chamber.

Designed for the self-assembly of the control kit, which is available as an option at an extra charge.

Combustion is controlled by means of an automatic draught regulator* or manually (*as an option at extra charge).

High combustion efficiency, up to 82%.

Certified boiler plates P265GH.

Quick and effective ash removal thanks to a cast iron, mobile grate.

60-month warranty for the leak-tightness of the water jacket.

24-month warranty for service life and efficient operation.

|

|

|

| Hard coal | Coke | Wood |

STANDARD

Automatically by means of a draught regulator

Manually by means of a screw adjusting the position of the flap in the lowest door

OPTIONAL

Automatically by means of an electronic controller (ZS-01)

| BOILER | Height | Width | Depth | A | B | C | Flue | Burning chamber | Charging hole | E | ||||

| D | height | width | depth | width | height | |||||||||

| SWK 10 | 917 | 318 | 640 | 253 | 806 | 962 | Ø 130 | 325 | 214 | 376 | 146 | 199 | 383 | 179 |

| SWK 14 | 917 | 380 | 680 | 253 | 735 | 957 | Ø 130 | 298 | 276 | 376 | 212 | 167 | 445 | 133 |

| SWK 21 | 956 | 506 | 707 | 280 | 753 | 996 | Ø 170 | 290 | 400 | 397 | 317 | 197 | 572 | 140 |

| SWK 28 | 1129 | 506 | 806 | 280 | 920 | 1166 | Ø 170 | 450 | 400 | 493 | 317 | 197 | 569 | 137 |

| SWK 35 | 1318 | 584 | 796 | 320 | 1100 | 1363 | Ø 190 | 470 | 460 | 490 | 380 | 330 | 649 | 178 |

| SWK 44 | 1318 | 584 | 966 | 320 | 1100 | 1363 | Ø 190 | 470 | 460 | 660 | 380 | 330 | 649 | 178 |

| Lp | Detailed data | Jedn. miary | SWK 14 | SWK 21 | SWK 28 | |

| 1 | Rated thermal output | kW | 14 | 21 | 28 | |

| 2 | Standard fuel | hard coal | ||||

| 3 | Charge capacity of the burning chamber | dm3 | 35 | 55 | 95 | |

| 4 | Boiler water capacity | dm3 | 33 | 50 | 70 | |

| 5 | Max. water temperature | °C | 95 | |||

| 6 | Min. required draught | Pa | 22 | 25 | 25 | |

| 7 | MMin. chimney height | m | 5 | 5 | 7,5 | |

| 8 | Flue diameter | cm´cm

Æ cm |

Æ 130 | Æ 170 | Æ 170 | |

| 9 | Min. chimney cross-section area | mm | 14 x 14

Æ 14 |

20 x 14

Æ 18 |

20 x 14

Æ 18 |

|

| 10 | Max. operating pressure | bar | 1,5 | |||

| 11 | Heat efficiency with standard fuel at rated power | % | do 82 | do 82 | do 82 | |

| 12 | Net weight | kg | 162 | 213 | 263 | |

| 13 | Overall dimensions | height

weihht depth (incl. flue) |

mm

mm mm |

917

380 680 |

956

506 707 |

1129

506 806 |

| ZĘBIEC boilers | Thermal output | Heated floor area [m2], based on the heat transfer coefficient of the walls (insulation) | |||

| U 1 [W/m2K] | U ~ 0,7 [W/m2K] | U ~ 0,5 [W/m2K] | U ~ 0,3 [W/m2K] | ||

| no insulation | ~5cm styrofoam | ~8cm styrofoam | ~10cm styrofoam | ||

| SWK 14 | 14 | 120 | 140 | 165 | 215 |

| SWK 21 | 21 | 180 | 210 | 250 | 355 |

| SWK 28 | 28 | 240 | 280 | 330 | 430 |

Draught regulator

A draught regulator in solid-fuel boilers is a thermostatically operated device for controlling water temperature in the boiler.

The thermostatic head of the regulator monitors the water temperature in the boiler and via levers and a chain actuates a flap to increase or reduce the airflow into the hearth.